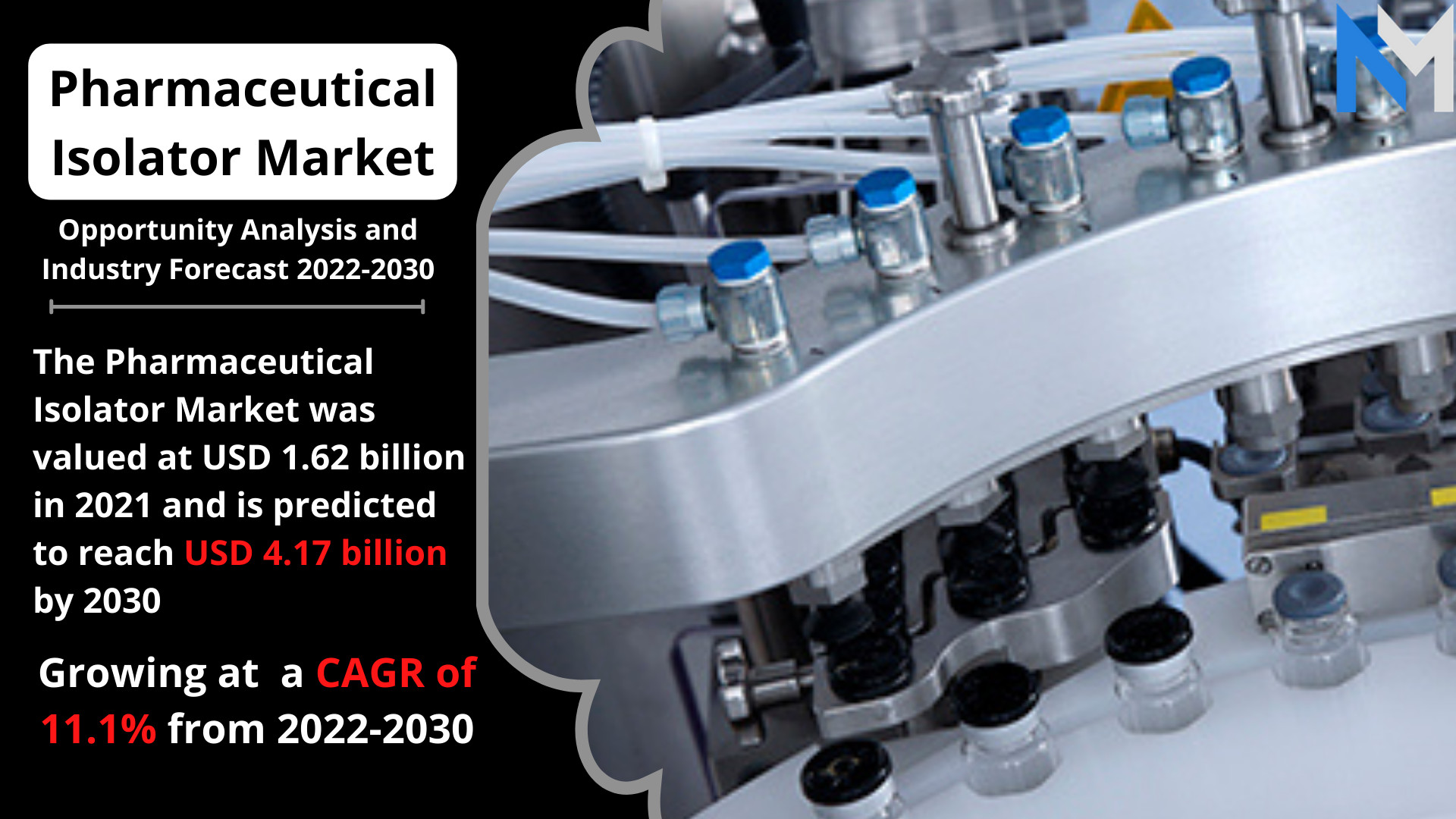

Pharmaceutical Isolator Market: A Booming Sector Driven by Demand for Sterile Products and Stringent Regulations

The pharmaceutical isolator market is experiencing significant growth, driven by a confluence of factors including the increasing demand for sterile products, the rising adoption of aseptic processing techniques, and stringent regulatory requirements. Pharmaceutical isolators, also known as sterile isolators, are enclosed units designed to provide a controlled environment for handling and processing pharmaceutical products, ensuring sterility and preventing contamination. They are widely used in various pharmaceutical manufacturing processes, from drug development to packaging, and are essential for ensuring product safety and quality.

Key Players in the Pharmaceutical Isolator Market

The pharmaceutical isolator market is dominated by a few key players, each offering a range of products and services to meet the diverse needs of the industry. These leading players are constantly innovating and developing new technologies to enhance the efficiency and effectiveness of their isolators. Some of the prominent companies in the market include:

-

Getinge: A global leader in medical technology, Getinge offers a wide range of pharmaceutical isolators designed for various applications, including sterile filling, lyophilization, and powder handling.

-

Pharmatech: Known for its expertise in cleanroom technology, Pharmatech provides a comprehensive range of isolators, from single-use to reusable systems, catering to the needs of small and large pharmaceutical companies.

-

Esco: A specialist in laboratory equipment, Esco offers a range of pharmaceutical isolators designed for various research and development applications.

-

Comatec: A leading provider of cleanroom solutions, Comatec specializes in designing and manufacturing pharmaceutical isolators for sterile production environments.

-

Terra Universal: Focused on providing high-quality equipment for research and development, Terra Universal offers a range of isolators specifically designed for pharmaceutical research laboratories.

Market Growth Drivers and Trends

The pharmaceutical isolator market is expected to witness sustained growth in the coming years, fueled by several factors:

-

Increasing Demand for Sterile Products: The global demand for sterile products, such as injectable drugs and biologics, is increasing, driving the need for pharmaceutical isolators to maintain sterility and product quality.

-

Stringent Regulatory Requirements: Regulatory authorities worldwide are enforcing strict guidelines and regulations for pharmaceutical manufacturing, emphasizing the importance of sterile processing and product safety. This has led to a surge in demand for pharmaceutical isolators to ensure compliance.

-

Growing Adoption of Aseptic Processing Techniques: Aseptic processing techniques, which aim to prevent contamination during pharmaceutical manufacturing, are becoming increasingly popular. This trend is further boosting the demand for pharmaceutical isolators, as they are essential for creating sterile environments for aseptic processing.

-

Technological Advancements: Advancements in technology, such as the development of single-use isolators and integrated systems, are enhancing the efficiency and flexibility of pharmaceutical isolators, making them more attractive to pharmaceutical companies.

Future Prospects and Challenges

The pharmaceutical isolator market is poised for significant growth in the future. The increasing adoption of isolators by pharmaceutical companies, combined with technological advancements and the rising demand for sterile products, will drive market expansion. However, the market also faces certain challenges, such as:

-

High Initial Investment: Pharmaceutical isolators can be expensive to purchase and install, which can be a barrier for some companies, particularly smaller ones.

-

Complexity of Operation: Operating and maintaining pharmaceutical isolators can be complex, requiring specialized expertise and training.

-

Competition from Alternative Technologies: Alternative technologies, such as sterile barrier systems, are emerging as potential competitors to pharmaceutical isolators.

Conclusion: A Bright Future for the Pharmaceutical Isolator Market

The pharmaceutical isolator market is expected to continue on a growth trajectory in the coming years, driven by the increasing demand for sterile products and the growing adoption of aseptic processing techniques. While challenges exist, the market is poised for continued expansion, driven by innovation and a focus on quality and safety in pharmaceutical manufacturing.

The Importance of Isolators in the Pharmaceutical Industry

The use of isolators is crucial in the pharmaceutical industry, as it ensures product sterility and prevents contamination. Isolators provide a controlled environment, isolating the pharmaceutical product from the external environment. This prevents the product from being exposed to dust, microorganisms, or other contaminants.

The Key Role of Pharmaceutical Isolators in Sterile Manufacturing

The pharmaceutical isolator market is a dynamic and growing sector, driven by the increasing demand for sterile pharmaceutical products. Isolators play a critical role in sterile manufacturing, ensuring product safety and quality. As the pharmaceutical industry continues to prioritize sterile processing and product safety, the demand for isolators is expected to remain robust.