The Rise of Warehouse Automation Systems: A Comprehensive Look

In today’s supply chain ecosystem, a better understanding of when to adopt warehouse automation is crucial. Warehouses play a critical role as hubs in the supply chain, acting as strategic centers for storage, distribution and inventory management. Optimizing through automation to ensure supply chain agility, cost-effectiveness and resiliency is imperative.

According to the Modern Materials Handling 2024 Automation Study with Peerless Research Group, the average material handling company invested $1.67 million on all equipment and solutions in 2023–up from $1.57 million the prior year. The majority of companies (20%) spent less than $100,000; 19% spent between $100,000 and $499,999; 17% allocated $2.5 - $4.9 million to material handling equipment and solutions; and 16% spent more than $5 million.

The research found that 66% of these companies plan on investing in automation within the next two years, up 6% from the previous year. They selected “improve warehouse capacity utilization” as their number one reason, followed by “improve picking efficiency” at 58%. “Improve utilization and reduce turnover” came in third at 57%, with “improve order accuracy” at 52% and “improve order cycle time” at 42%, rounding out fourth and fifth.

Why Warehouse Automation? Benefits and Drivers

Understanding the optimal timing for adopting warehouse automation is crucial for maintaining agility, cost-effectiveness and resiliency in supply chains.

The Warehouse Automation System market is expected to grow significantly over the next five years. The increasing demand for efficient and scalable logistics solutions, advancements in automation technology, and the rise of e-commerce are driving this growth. The market is also benefiting from the adoption of technologies such as robotics, AI, and IoT in warehouse operations. New entrants will find opportunities in developing innovative automation solutions or targeting specific industry needs. The market's growth is supported by ongoing trends in logistics and the increasing need for advanced automation systems.

Key Benefits of Warehouse Automation Systems:

- Increased Efficiency: Automating tasks like picking, packing, and sorting leads to faster processing times and reduced labor costs.

- Enhanced Accuracy: Warehouse automation systems minimize human errors, resulting in greater accuracy in order fulfillment and inventory management.

- Improved Productivity: Automation allows employees to focus on more complex and value-added tasks, boosting overall productivity.

- Scalability and Flexibility: Warehouse automation solutions can be easily scaled to meet changing demands and adapt to evolving business needs.

- Data-Driven Insights: Automated systems capture valuable data, providing insights into operational performance and facilitating data-driven decision-making.

Drivers Fueling Market Growth:

- E-commerce Boom: The rapid growth of online retail has created a surge in demand for efficient warehouse operations to manage increasing order volumes.

- Labor Shortages: The ongoing challenge of finding and retaining skilled warehouse workers is driving the adoption of automation to fill labor gaps.

- Technology Advancements: Continuous innovations in robotics, AI, and IoT are making warehouse automation more sophisticated and accessible.

- Supply Chain Optimization: Businesses are increasingly seeking to optimize their supply chains for greater speed, agility, and resilience.

Navigating the Warehouse Automation Landscape

Understanding the best approach to adopting new technology into an intralogistics ecosystem can be daunting. Where to start? What’s the best warehouse and equipment technology? Which offers the best ROI? How long will it take to implement, and what level of training will be required? As the vice president of EQSOLUTIONS at Equipment Depot, I advise companies every day not to conduct their warehouse evaluation in a vacuum—this process is a highly complex activity with many moving parts. In fact, companies are unaware of many new solutions that can positively impact a business’s overall outcomings. I highly recommend partnering with a material handling systems integrator with a pulse on innovative solutions. The benefit of a team specifically built to advance and optimize a warehouse would be a prudent investment.

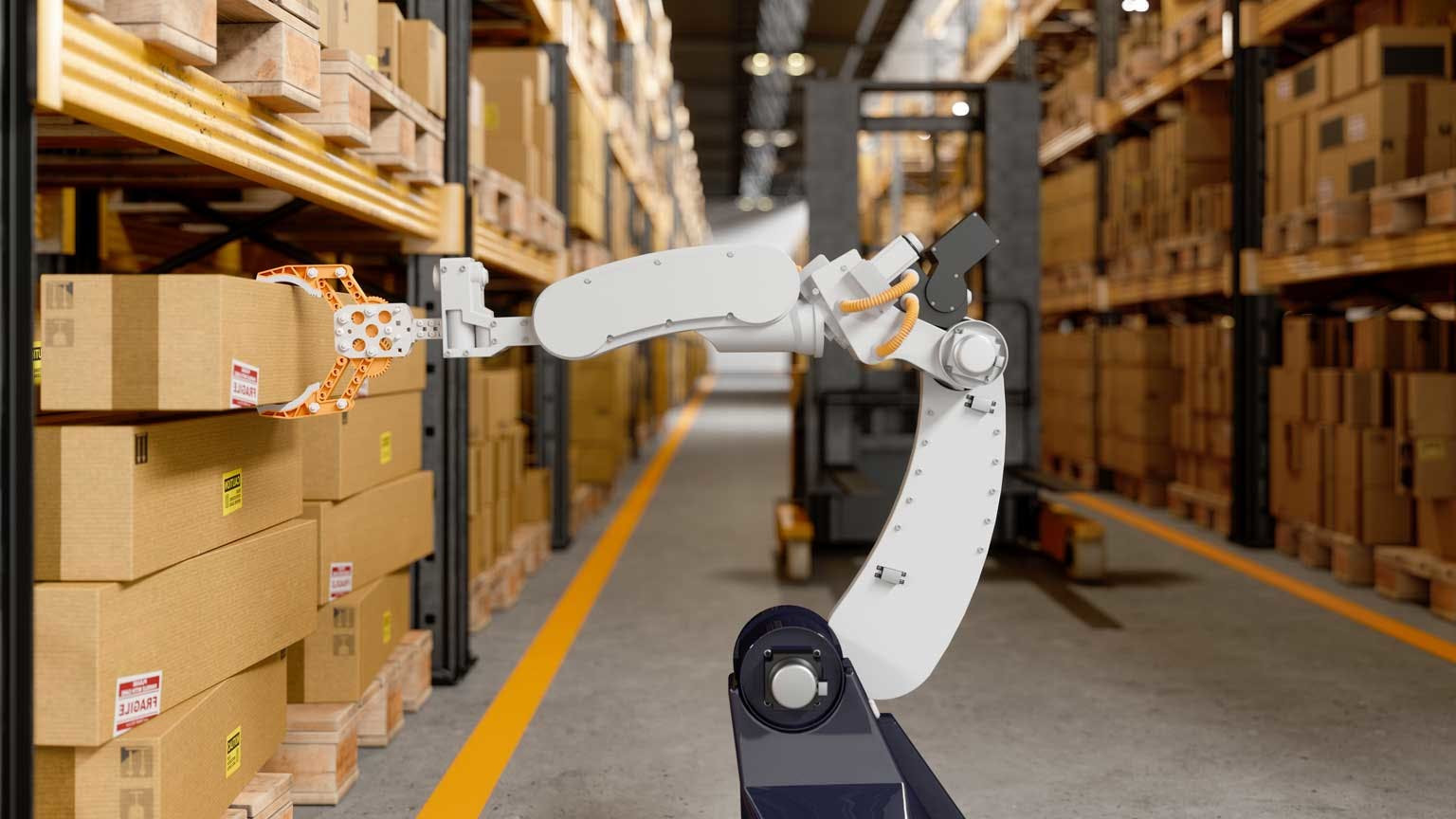

One part of the process is finding the right mix of equipment and the benefits it brings to the overall supply chain solution. From semi-automated to fully automated equipment, such as Automated Guided Vehicles (AGVs), robotics, conveyors, and automated storage and retrieval systems (AS/RS), below is a breakdown of various types of equipment solutions that may be a perfect fit depending on the situation.

Choosing the Right Equipment:

- Automated Guided Vehicles (AGVs): AGVs are self-driving vehicles that transport goods throughout the warehouse, eliminating the need for manual operation.

- Robotics: Robots can perform tasks like picking, packing, and palletizing, increasing efficiency and reducing labor costs.

- Conveyors: Conveyor systems move goods along designated routes, optimizing material flow and minimizing manual handling.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS are automated storage systems that optimize storage space and retrieval processes.

The Future of Warehouse Automation

As the warehouse and material handling industry continues to evolve, its effects on intralogistics and supply chain dynamics can be beneficial or adverse, depending on the level of proactiveness or reactiveness. The time for companies to assess their warehouse and supply chain network and consider a plan for adopting automated solutions is now. Depending on needs, the company and the overall marketplace, there is a wide range of automation solutions that can provide significant improvements in productivity and efficiency while reducing labor costs and improving customer satisfaction.

Trends Shaping the Future:

- Artificial Intelligence (AI): AI is being integrated into warehouse automation systems to enhance decision-making, optimize workflows, and improve predictive analytics.

- Internet of Things (IoT): IoT connectivity enables real-time data collection and monitoring, providing insights into warehouse operations and optimizing performance.

- Cloud Computing: Cloud-based platforms offer scalable and flexible solutions for warehouse automation, facilitating data storage, analytics, and remote management.

- Sustainable Automation: Companies are increasingly adopting sustainable automation practices to reduce energy consumption and minimize their environmental footprint.

Conclusion: The Time is Now for Warehouse Automation

The Warehouse Automation System market is experiencing rapid growth, driven by a confluence of factors, including the e-commerce boom, labor shortages, technological advancements, and the need for supply chain optimization. By embracing automation, businesses can unlock significant benefits in terms of efficiency, accuracy, productivity, scalability, and data-driven insights. The time to act is now, as companies that fail to adapt to this evolving landscape may fall behind in the competitive market.