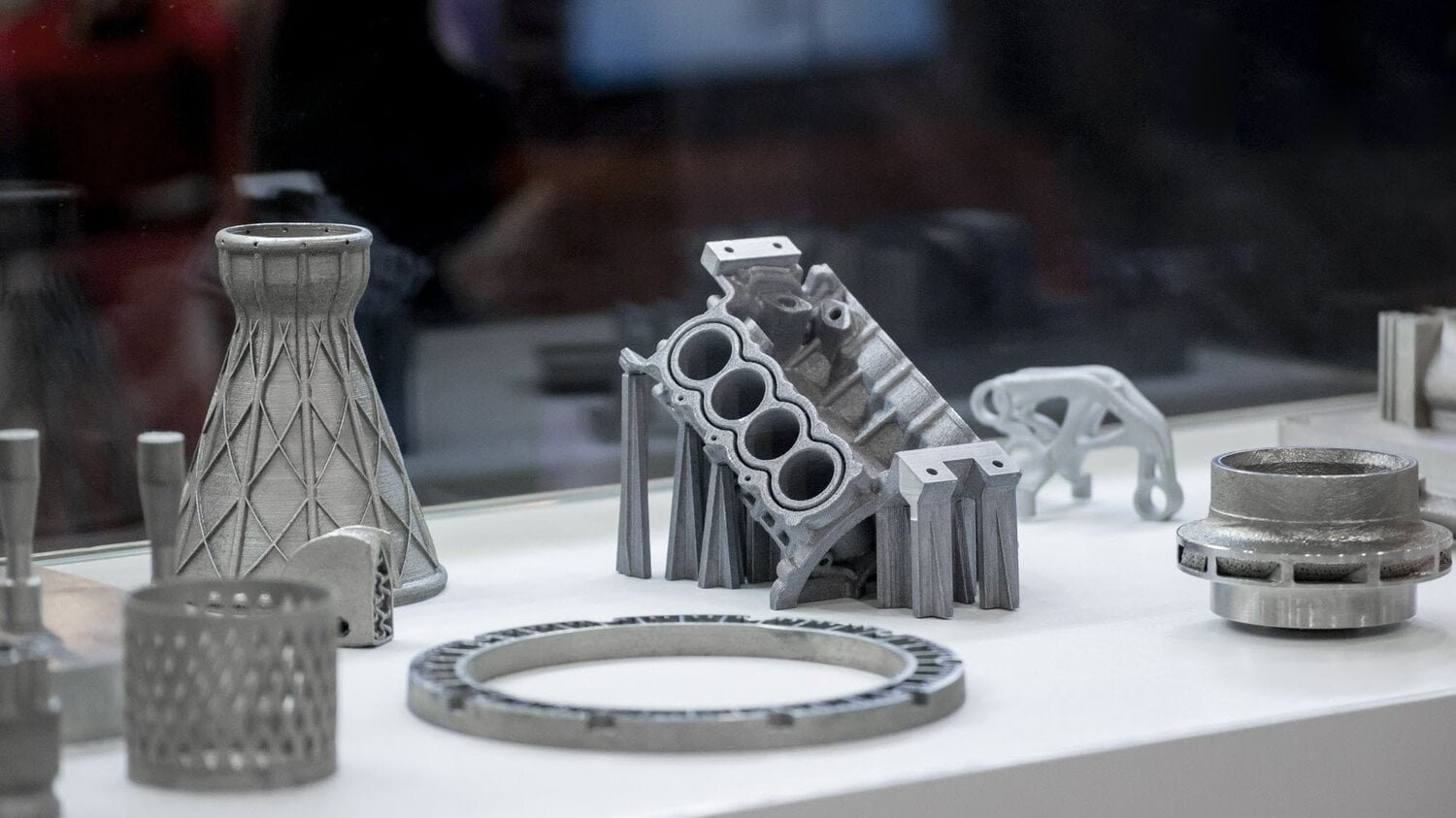

With design freedom, rapid production, lower costs, and lightweighted products, 3D printing has revolutionized industries from aerospace to healthcare. 3D printing became a reality when Charles Hull patented his Stereolithography (SLA) printer back in 1986, which was capable of printing only acrylic-based 3D objects. However, 3D printing supports a variety of materials today, namely plastics, resins, metals, concrete, composites, etc. With metal 3D printing constituting >50% of the total 3D printing market today, the 3D printed metal parts industry is expected to have a US$15 bn market in 2024 (projection by Stratview Research).

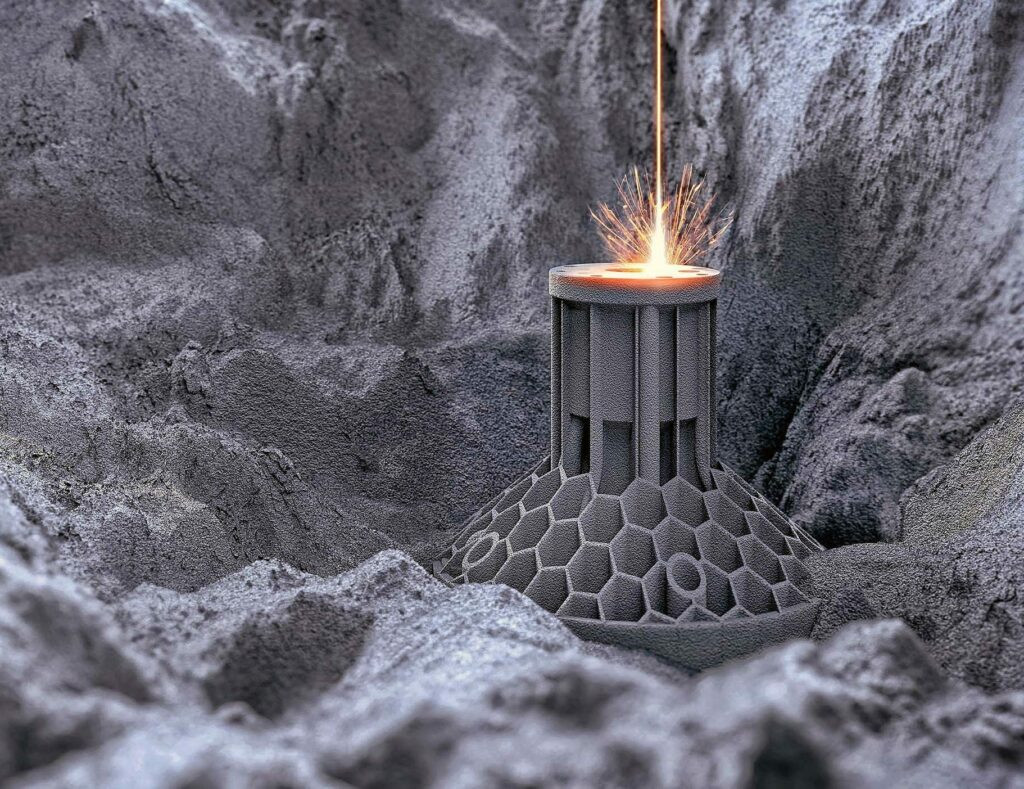

Conventional metal 3D printing involves methods like Powder Bed Fusion (PBF), Selective Laser Sintering (SLS), Direct Metal Deposition (DMD), etc. Developed back in the 1980s, PBF remains the dominant manufacturing method, accounting for around 40% of all metal parts manufactured by 3D printing. The method uses an electron beam, heat, or laser to melt the metal powder.

Apart from the conventional techniques, the industry is continuously looking towards innovations to reduce lead time, material waste, cost per product, and automation. For instance, Boeing HorizonX invested in Digital Alloys, a startup founded in 2017, and developed ‘Joule Printing,’ which not only offers to process nearly any metal but uses thin metal wires as a raw material replacing the comparatively expensive metal powders (3D-printing grade Titanium 6AI-4V powder is approximately 141% more expensive than its wired counterpart).

NASA wanted to test a fuel injector for its Space Launch System powering the Orion spacecraft in 2013. Amazingly, NASA got it ‘printed’ by Aerojet Rocketdyne instead of the traditional manufacturing process, and the results left everyone impressed. 3D printing the injector not only reduced the production time from 1 year to just 4 months and the number of parts from 160 to 2 but also reduced the total production cost by 70%. This was only a brief demonstration of the scope of benefits offered by 3D printing. Manufacturing metal parts using 3D printing has a lot to offer.

Conventional manufacturing demands the preparation of molds and a production line before the design can hit production, which could take weeks or even several months in many cases depending on the complexity of the design. On the other hand, 3D printing eliminates these preparatory steps, facilitating production immediately after design. This not only brings down the cost of production but also enables rapid prototyping, allowing the R&D teams to perform multiple iterations in a stipulated time frame.

Did you know that as much as 90% of the metal is cut away during manufacturing processes in the aerospace industry? Also in traditional manufacturing, raw material cost constitutes around 40% of the total production cost on average, making material waste a high monetary hit on the pockets of the manufacturers. 3D printing guarantees nearly negligible wastage in the process as it puts material only in the required areas rather than carving out/cutting the unwanted parts.

Design and manufacture of lightweight parts becomes essential as every kilo matters in a space mission costing thousands of dollars per kilo, every gram matters when placing a medical implant in a human body, and so on. 3D printing allows structural optimization and novel design, allowing engineers to design as much as 70% lighter parts with the same applicability and structural strength. For example, Atos and Materialise reduced the weight of titanium inserts used in satellites by 66% through topology optimization and lattice structure design in 3D printing.

Additionally, enabling precision manufacturing of geometrically complex (like internal channels, lattice structures, etc.) parts by eliminating the need for molds, drastic reduction in the number of parts (20 separate pieces replaced by a single Fuel Nozzle tip for GE’s LEAP engine using 3D printing), support for low volume manufacturing, etc. are some of the other key benefits delivered by 3D printing.

Accounting factors like the elimination of preparatory steps, waste reduction, weight reduction, and monolithic designs make it apparent that the overall cost of parts manufactured by 3D printing is much lesser than conventional processes in most cases, with some exceptions depending on industry and scale.

3D-printed metal parts have been widely adopted by multiple industries like aerospace, defense, automobiles, healthcare, and electronics, thanks to the benefits discussed.

The aerospace and defense industry requires the production of geometrically complicated parts, and it usually has a high overall prototyping time. 3D-printed metal parts serve as a reliable fix to the issue. Apart from cost and weight reduction, 3D printing also allows supply chain flexibility to this industry, and hence, this industry is the largest consumer of 3D-printed metal parts, reflected by the fact that this industry drives more than 60% of the 3D-printed metal parts market.

3D printing is now being employed to fabricate metal parts previously manufactured using conventional methods. Multiple components like the fuel nozzle tip(s) for GE Aviation’s LEAP engines (25% weight cut, no. of parts reduced from 20 to just 1), titanium nose-landing gear brackets for Airbus aircraft (100% increase in stiffness, 29% weight reduction), along with Aerojet Rocketdyne’s Bantam rocket engine components, Raytheon’s 3D-printed guided missiles, metal components for Stryker vehicles by General Dynamics, etc. are examples of great application of 3D-printed metal parts in this industry.

3D-printed metal parts also aid the automobile industry by enabling lighter and more efficient components, as well as rapid prototyping and customization. Hence, 3D printing has been a long-term partner for this industry and is now also used for production models widely. For instance, most car manufacturers in the world use 3D printing to implement innovative design languages, weight reduction, and eventually, improve the vehicle's fuel economy. Volkswagen is the largest implementer of 3D-printed parts in the production models, followed by BMW and Ford. Moreover, nearly all major manufacturers leverage the technology to manufacture parts like fuel injectors, brake calipers, rotor components, cylinder heads, pistons, seat frames, etc. Some examples include Spoiler brackets in Buggati vehicles (around 53% weight reduction), Ford F-150’s aluminum engine manifold, etc.

3D-printed metal parts are making an impact in various other industries, such as healthcare. Talking of the healthcare industry, orthopedic implants (like custom-fit hip and knee replacements), dental implants, prosthetics and complex dental restoration (like metal crowns, bridges, and dentures), custom surgical instruments, cranial and maxillofacial implants, and patient-specific surgical models are some of the widely-implemented 3D metal units. Companies like Zimmer Biomet and Stryker provide custom identical implants for every patient according to his/her needs using patient scans like CBCT or CT scans and 3D printing, which is almost impossible using mass production methods.

Furthermore, 3D printing is being adopted for manufacturing of metal parts and tools in companies like Sandvik Coromant (custom cutting inserts and tools), Kennametal (wear-resistant components for industries such as mining and oil drilling), DMG Mori (components for CNC machines), Trumpf (high-precision nozzles for laser cutting systems), etc.

The widespread adoption of 3D-printed metal parts, as discussed in the paragraph above, is a testament to its potential to reshape the metal manufacturing landscape.

There are challenges like expensive 3D printers and metal powders, the need for support structures, limited availability of printable metals, etc. that have kept the technology away from complete mainstream. However, the industry is determined to bring innovations and mitigate the drawbacks mentioned. For instance, HP’s Metal Jet printer (allows automatic removal and reuse of loose metal powder, supports new materials like IndoMIM M2 Tool Steel and Osprey 316L and is suitable for production at scale), Nikon SLM Solutions and Howco Metals Management LLC’s partnership (to develop niobium-based C103 alloy for 3D printing) are some examples depicting industry’s interest in research and development.

In a nutshell, by allowing unparalleled design freedom, rapid production, negligible material wastage, reduced number of parts, lightweight products, and most importantly, reduced cost of manufacturing, the technology is revolutionizing industries from aerospace to healthcare. According to Stratview Research, the global 3D-printed metal parts market is expected to grow at a CAGR of 30.2% and hit $43.9 billion by 2028. Hopefully, the ongoing research and development, along with the increasing adoption of the technology, will unlock new horizons of profitability, rapidity, and convenience for various other industries in the coming years.