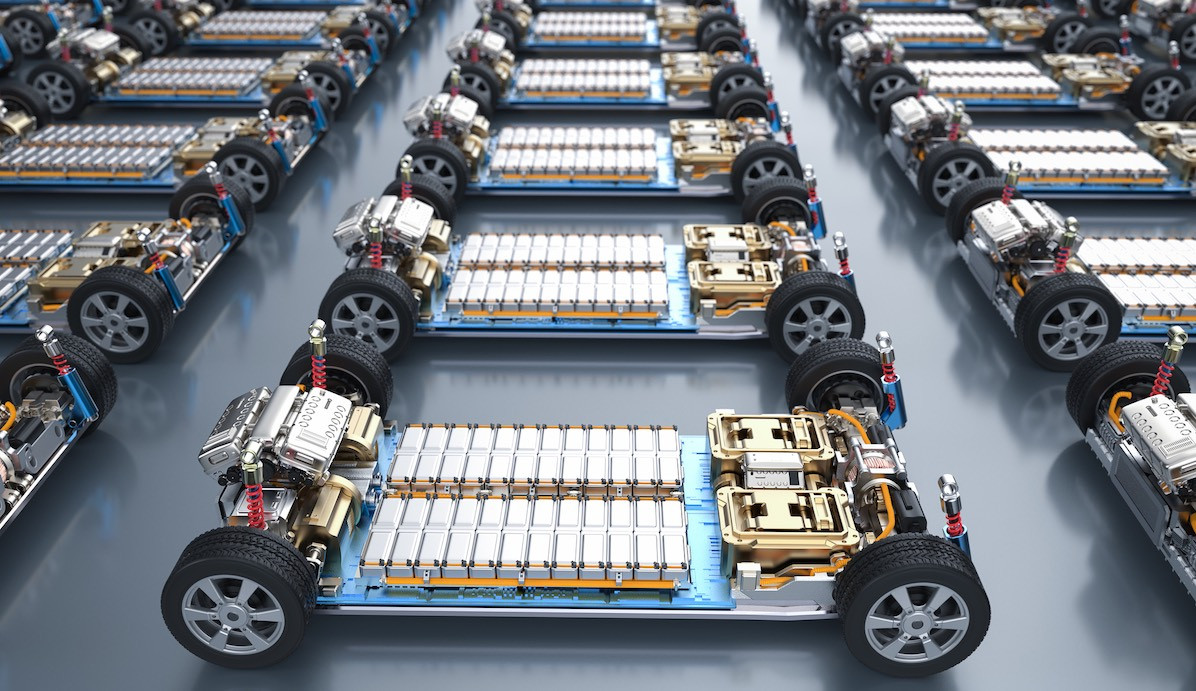

Researchers from the University of Graz in Austria say they have developed a compact system for recycling lithium-ion batteries used in electric vehicles (EVs) that they hope will enable cost-effective and environmentally friendly recycling. The innovation is intended to enable the cost-effective and environmentally friendly recycling of valuable raw materials directly on-site. The first prototype has been completed and is located on the university campus, ready for use. Currently, the focus of the project will lie on automotive batteries, and mobile phone or laptop batteries “are initially excluded,” implying that the scope of the project may be broadened at a later date.

The project was launched by Jürgen Abraham, Tobias Kopp and Chris Pichler who are now working on the solution as part of a spin-off from the University of Graz at the UniCorn start-up incubator under the project ‘ProtectLiB.’ This is where they developed the compact container-sized recycling plant.

The ProtectLiB Recycling Process

The size of an ordinary container, the recycling process allows vehicle batteries to be recycled directly onsite and, according to Kopp, “can separate lithium, cobalt and nickel from the liquid electrolytes” and can do so without heat, making the recycling process safer and significantly cheaper. While the specifics of the recycling process are unknown, ProtectLiB describes the process on their LinkedIn page as consisting of a machine that safely shreds the batteries, a mechanical separation phase, followed by a chemical post-treatment phase which uses wastewater and acids to wash out the individual components. Energy required for the process comes from the surpluses from other processes.

The recycling process reportedly reduces emissions by up to 70 per cent compared to mining for new raw materials and can safely recycle damaged and critically damaged batteries, while also being the only recycling process to entirely eliminate fire hazards. This makes it a much safer and more sustainable option for handling end-of-life EV batteries.

Prototype and Expansion

A first prototype of the recycling technology is located on the campus of the University of Graz, while ProtectLiB has already secured a first unnamed customer. “Battery prototypes for transport are being developed there,” said Kopp. “In future, the technology of ProtectLiB will enable the company to recycle these directly on site.”

While the current prototype is focused on recycling EV batteries, ProtectLiB is hoping to one day expand its process to be able to recycle batteries from mobile phones and laptops. However, as every battery has a different chemical composition, these smaller consumer batteries are initially excluded from being recycled in ProtectLiB’s prototype.

The Future of Battery Recycling

ProtectLiB’s innovative recycling process has the potential to revolutionize the way we recycle EV batteries. By making the process more efficient, cost-effective and environmentally friendly, the company is helping to create a more sustainable future for electric vehicles. As the demand for electric vehicles continues to grow, the need for sustainable battery recycling solutions will become even more critical. ProtectLiB’s technology is a promising step in the right direction.

The company’s commitment to sustainability is evident in their focus on reducing emissions and eliminating fire hazards. Their recycling process is designed to be safe, efficient and environmentally friendly, which is essential for ensuring the long-term viability of the electric vehicle industry. In a LinkedIn post, the project initiators outlined three takeaways: OEMs produce batteries globally, yet recycling is local, which poses particular challenges, such as the granularity of the specified contents. Additionally, the digital battery passport will only enhance sustainability and circularity if it is done correctly and access privileges are sensibly defined. Finally, the initiators state that it needs to be clarified who is responsible for the accuracy of the gathered data, who has access to it, and for how long.

The development of ProtectLiB’s recycling process is a significant step forward in the quest for sustainable battery recycling solutions. The company’s innovative approach to recycling, combined with its commitment to environmental sustainability, makes it a leader in the field. As the demand for electric vehicles continues to grow, the need for sustainable battery recycling solutions will become even more critical. ProtectLiB’s technology is a promising step in the right direction.