The Rise of Carbon Fiber: A Material Revolution Shaping Industries

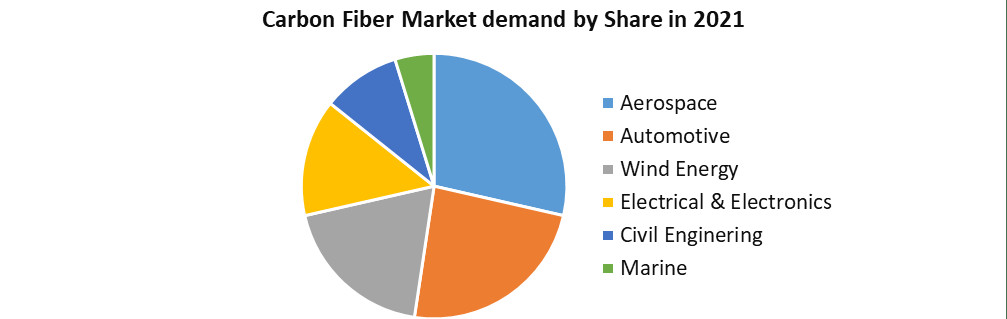

The global large tow carbon fiber market is poised for remarkable growth, projected to reach a staggering $1775.48 billion by 2031, according to InsightAce Analytic Pvt. Ltd. This surge is driven by a confluence of factors, including the increasing demand for lightweight materials in industries like aerospace, automotive, and energy. Carbon fiber, with its exceptional strength-to-weight ratio and durability, has emerged as a key player in this material revolution.

Aerospace & Defense: Carbon Fiber Takes Flight

The aerospace and defense sector is a major driver of carbon fiber demand. The material's lightweight properties are essential for reducing aircraft weight, leading to improved fuel efficiency and performance. Vertical stabilizers, floor beams, engine nacelles, wings, and elevators are just a few of the aircraft parts that can be made with carbon fibers. Manufacturers are successfully taking advantage of the expanding potential in the worldwide aerospace & defense sector.

Rising defense budgets are fueling the desire for lightweight building materials and lower running costs for national security across nations, driving up carbon fiber usage. Additionally, the emergence of 3D printing technology is further boosting the use of carbon fiber in aerospace applications. 3D printing allows for the creation of complex and intricate parts, leading to greater design flexibility and reduced manufacturing costs.

Automotive: Lighter, Faster, and More Efficient

The automotive industry is another significant market for carbon fiber. The growing demand for fuel-efficient vehicles has spurred the adoption of lightweight materials, and carbon fiber composites are a prime contender. According to a report provided by the United States Department of Energy, a 10% reduction in automotive weight can result in a 6 to 8% gain in fuel economy. Carbon fibre composites are both practical and lightweight, making them ideal for a wide range of automotive applications.

Carbon fiber is increasingly used for vehicle body parts such as fenders, deck lids, bumper beams, and hoods. This material enhances vehicle durability, leading to longer-lasting auto parts. Furthermore, carbon fiber's strength and stiffness make it particularly suitable for high-performance sports cars and luxury vehicles, where weight reduction and enhanced performance are paramount. Companies are implementing tactics and investing in procedures that can lighten the entire vehicle's weight. As a result, high-end supercars frequently use carbon fiber reinforced polymer (CFRP).

Challenges and Market Dynamics

While carbon fiber holds immense promise, there are challenges to its widespread adoption. The primary obstacle is its higher cost compared to traditional materials like metal. The price of carbon fiber is directly impacted by the yield and price of the precursor used in its production, further complicating the cost equation. Despite its advantages, the price barrier remains a significant hurdle for some industries.

Regional Trends: Europe, North America, and Asia-Pacific Lead the Way

The European large tow carbon fiber market is projected to hold a substantial share in revenue and is expected to grow at a rapid rate. This region's focus on sophisticated lighter materials, particularly in industries like energy and automotive, is driving the demand for carbon fiber. Germany and Mexico are leading the charge in this shift towards modern materials.

The North American market is also poised for significant growth, fueled by advancements in infrastructure, pricing, and product innovation. Research and development initiatives are playing a crucial role in shaping the future of the carbon fiber industry in the region.

The Asia-Pacific region, with its burgeoning automotive and aerospace sectors, is another key market for carbon fiber. As the region's economies continue to grow, the demand for lightweight and high-performance materials is expected to soar. China, in particular, is a major player in the global carbon fiber market.

The Future of Carbon Fiber: A Sustainable and Innovative Path

As the world seeks solutions for environmental sustainability and technological innovation, carbon fiber is well-positioned to play a vital role. Its use in wind energy, construction, and other sectors is expected to expand as industries strive for more sustainable and efficient practices. The ongoing development of new manufacturing techniques, such as 3D printing, further enhances carbon fiber's potential for wider adoption across diverse applications.

Conclusion: A Material with a Bright Future

The global large tow carbon fiber market is on an upward trajectory, driven by its exceptional properties and the growing need for lightweight and durable materials in various industries. With its potential for innovation and sustainability, carbon fiber is poised to play an increasingly important role in shaping the future of manufacturing and technology.